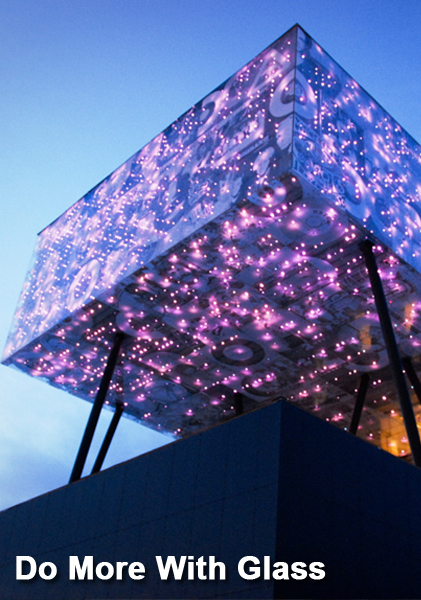

DIGITAL PRINTED Glass

WHTB architecture & design

WHTB architecture & design

From the initial design stage, through the value engineering process, we can assist architects designers and engineers with calculating the long-term savings enabled by digital ceramic printed glass. Digital ceramic in-glass printing meets complex functional performance requirements.

It enables control of all special elements of architectural and designed glass

TRANSLUCENCY/OPACITY

LIGHT DI¬FFUSION AND TRANSMISSION

SOLAR HEAT GAIN COEFFICIENCY

ENERGY EFFICIENCY

PRIVACY LEVELS

ELECTRICAL CONDUCTIVITY

SLIP RESISTANCE

ANTI-BIRD COLLISION

ANYWHERE- Exterior and interior durability. Ceramic ink resistance after tempering is equal to glass resistance.

ANYDESIGN- Personalized, opaque, transparent and textured-look effects. Micro-drop precision enables highly detailed, accurate photorealistic and graphic designs and gradients.

ANYNEED- Any aesthetic requirements and a wide range of functional applications. Micro-drop precision supports light diffusion, light transmission, energy efficiency, sun control, temperature control, privacy levels and other functional requirement.

ANYCOLOR- Multi-color printing in a single glass. Digital in-glass printing technology enables truly limitless multi-color designs with ceramic ink durability.

ANYSIZE- From small panes to building facades, with perfect-registration multi-pane printing. Modular printer hardware and advanced printing software enable simple and flexible printing on glass panes.

ANYCONDITIONS- Full resistance to weather and chemicals. Ceramic inks fused into the glass stand up to harsh weather conditions and are scratch and acid-resistant, ideal for exposed, high-traffic and graffiti-prone installations.

Digital printed glass capabilities

Print resolution: 360dpi (real)

Maximum Size : 3300 mm x 6000 mm(130″x236″)

Minimum Size : 200 mm x 300 mm (8″x12″)

Thickness: 2 mm -19mm (0.08″-0.75″)

Image format All popular graphic formats including PDF, PS, EPS, Tiff, BMP and JPEG

Code Compliance: GB 15763.2 ASTM C1048 AS/NZS 2208 BS/EN 1215